JPT MOPA M7 100W FIBER LASER MARKING MACHINE

Bring your ideas to life with our versatile JPT M7 MOPA fiber laser engravers!

Amazing MOPA fiber laser marking machine for color marking

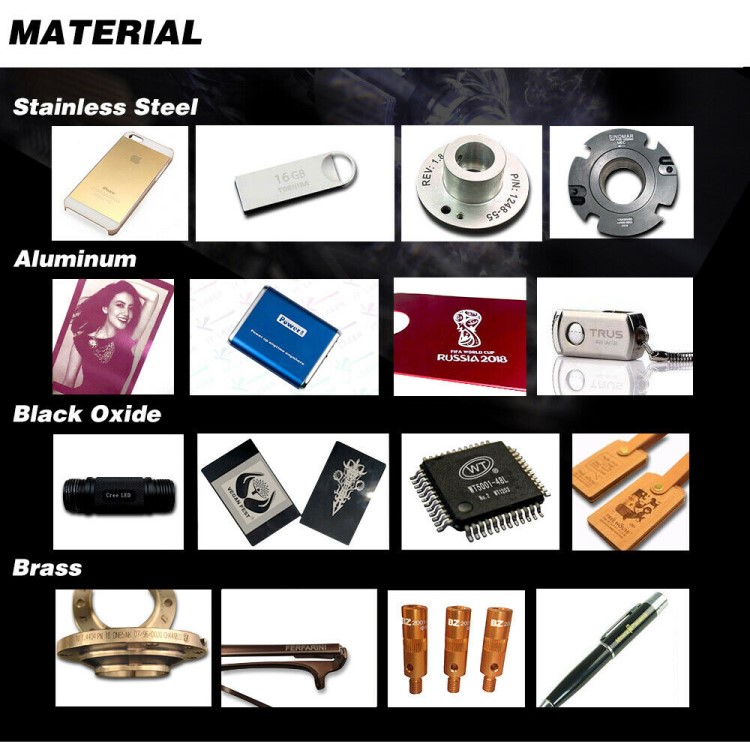

This split type 100W JPT MOPA fiber laser engraver is your ultimate resource for marking or engraving words, logos, pictures, barcodes, and more on metal (including personalized gold and silver jewelry!) and other materials with a quick turnaround and perfect accuracy. Our device's state-of-the-art JPT M7 MOPA air-cooled fiber laser source avoids the tetchiness, fragility, and water-based mess of CO2 laser tubes. Instead, it provides solid-state efficiency, quality, stability, and durability for its entire service life of 100,000 hours. The optical amplifier boosts the beam produced by the master oscillator, with independently adjustable pulse frequency and width to offer incredible versatility applicable to a wide range of materials, ideal for colorful markings on stainless steel and black etchings on anodized aluminum.

The Galvo-Tech galvanometric system and compact Singapore Wavelength Fθ field lens ensure quick work with less than 1% distortion from your design. The built-in workspace grid and laser locators make calibrating everything fast and easy. Rotary axes are not included but plug-and-play connection is provided for units with 4-pin connections to mark curved surfaces such as gold and silver rings and bracelets.

The desktop MOPA Fiber laser engraver is operated from the bundled edition of EzCad2, compatible with 32 and 64-bit editions of Windows XP, Vista, 7, 8, and 10. Of course, this MOPA fiber marking machine ships with abundant insulation and padding to ensure it arrives at your door like it just came off the factory floor. For all your projects cutting and marking metals, gems, silicon, and more, you can do no better.

Product Parameters

|

Model |

JPT M7 -E |

|

Laser power |

30W/60W/80W/100W |

|

Laser Source |

JPT MOPA M7 Fiber Laser Source |

|

Galvanometer |

Sino-Galvo Scanning Head |

|

Control Board |

Original BJJCZ Control Board |

|

Power Supplies |

MeanWell |

|

Software |

EZCAD2 for Windows 64-bit 7/8/9/10/11 |

|

Dual Red Dot Device |

Easy focusing for 2 lens sizes |

|

Z-Axis Control |

Manual Lift/Motorized |

|

F-Theta Field Lens |

Singapore Wavelength Field Lens |

|

Output fiber length |

2m |

|

Working area |

110*110mm/200*200mm |

|

Color |

Bule grey /Grey red/Silvery |

|

Pulse width |

2-350ns |

|

Adjustable frequency range |

1-4000kHz |

|

Typical beam quality, M2 |

<1.3 |

|

Pulse energy max |

0.8mJ |

|

Output power stability |

<5% |

|

Output beam diameter |

7±0.5mm |

|

Average output power |

>30 |

|

Re-position precision |

0.002mm |

|

Minimum line width |

0.01mm |

|

Minimal character |

0.1mm |

|

Supply voltage |

24V |

|

Demand current |

<6% |

|

Cooling way |

Air Cooled |

|

Working environment |

Clean and dust-free or less dust |

|

Humidity |

45 ~ 85% (non-condensing) |

|

Laser lifetime |

> 100,000 hours |

|

Operating temperature |

0 ~ 40℃ |

|

Marking format |

Graphics, text, barcodes, QR code, auto date, batch number, serial number, etc. |

|

Support graphic format |

Ai, plt, ;dxf, dst, svg, nc, bmp, jpg, jpeg, gif, tga, png, tiff, tif |

|

Colorful Marking Application: |

stainless steel/black marking oxygen aluminium |

|

Engraving Material Application |

Aluminum, Stainless Steel, Brass, Copper, nonmetal such as nylon, light button, ABS, PVC, PES,etc |

|

Applicable industries |

iPhone back logo, TV controller keyboard, laptop keyboard, mobile phone keyboard, translucent plastic keys, etc |

|

Packing size (L * W * H) |

75*65*50cm |

|

Net / gross weight |

60kg/70kg |

High-quality, JPT MOPA M7 laser source, with a wide range of frequencies (1-4000 kHz) and modifiable pulse width which allows doing engravings in color on metals.

Compact and portable, the desktop model has a small footprint and could be easily transported to the worksite.

Flexible, the open design and adjustable Z-Axis allow to work on objects of different shapes and sizes up to 30” in height.

Practical, dual red dot easy focusing device for 2 lens sizes and work area LED lights.

Easy operation with EZCAD2 software that supports all standard design file formats AI, DXF, DST, PLT, BMP, JPG, GIF, TGA, PNG,TIF, etc.

2-year Manufacturer Warranty for products and parts against defects in materials or workmanship, from the original date of receipt for MOPA fiber lasers.

24*7 Online technical support. Contact our customer support in case you have any question regarding installation or operation of JPT MOPA Fiber Laser Color Marking Machine.

Operation Software system in English(muti-language supported). EZCAD2 is a well-known and most popular laser and galvo control software.

JPT M7 MOPA Fiber Laser Source

Enjoy stable dependable operation with an MTTF over 100,000 hours thanks to this engraver's solid-state JPT MOPA laser source. Its optical amplifier boosts the beam produced by the master oscillator, with independently adjustable pulse frequency and width to offer great versatility applicable to a wide range of materials.

Frequency and pulse width of laser are independently controlled

Marking plastics and other sensitive materials Pickling anode, pickling coating Marking colored stainless steel Marking black anodized aluminum.

Sino-Galvo Scanning Head

The laser arm's Sino-Galvo drive and scanning system provides outstanding accuracy and works with the Fθ lens to produce both fast and stable marking of flat surfaces at speeds as fast as 7000mm/s per second The galvanometer has good operating stability, high positioning accuracy, fast marking speed, and strong anti-interference ability.

The standard mechanical scan angle is ± 11 ° and the maximum mechanical scan angle is ± 15 °.

Re-position precision is 0.002mm; High-Rate of Electrical-Optical Conversion: up to 70%

JPT MOPA Fiber Laser Marking Engraving Machine Main Configuration:

*BJJCZ Motherboard

The dependable Beijing JCZ Tech control board organizes all of the aspects of this long-lasting multifunctional fiber laser marker and keeps them humming along.

*Full Color Marking

Quickly and easily create dark marks on anodized aluminium or full color images and patterns on stainless steel, titanium, and chromium thanks to the easy frequency modulation allowed by this engraver's MOPA design.

* Red Dot Guidance

Visible laser pointers help make focusing quick and easy. The built-in red laser locator calibrates with the laser's scanner to allow precision work on the machine's workbed.

* Convenient Manual Focus

Achieve consistent focus on various materials using the support column's helpful ruler. Rotate the focus-height wheel for quick focusing on every material.

*Multifunctional Workbed

The workbed is compact and lightweight with a simple interface. The built-in grid allows convenient and safe adjustment of the laser's position. Its M5 holes can be fitted with positioning bars to keep your material just where you need it.

EZCAD2 Software

INCLUDEDLightBurn Compatible

1.EZCAD2 is a well-known and most popular laser and galvo control software. It works with LMC series laser controller for laser

processing like marking, engraving, etching. After 15 years of verification by the market, It is now adopted by more than 4000 laser equipment integrators, more than 100,000 laser machines are with EZCAD2 annually.、2.Your EzCad2-based fiber laser engraver works with LightBurn's latest galvo functionality on Windows, MacOS, and Linux systems to let you create even the most intricate patterns easily.

Rotary Axis

Rotary Axis is a great accessory to add to your fiber laser machine. It allows you to engrave on cylindrical items like cups,pipes, pens, rings, etc. It comes in different sizes; the standard models are #80 and #125. You can always buy a rotary axis later, but don’t forget to mention it to us so that you will get the machine ready for this addition. When purchasing it together with the laser machine, you get a package deal. If you need a larger size or jewelry-type rotary axis, let us know, and we will deliver you the product that meets your

requirements.

Colour marking stainless steel

Annealing is a process that does not remove material during processing. The creation of colours when laser marking stainless steel with the annealing method is caused by heat application. Whilst the possibility of creating colours with a laser machine has been around for a long time, the capability to accurately precisely mark colours and to reproduce them is a newer advantage provided by a MOPA laser source.

Black marking of anodised aluminum

The top layer of anodised aluminium is usually removed by a laser to reveal a white mark. A mark of this kind is particularly visible and clear on coloured anodized surfaces, but on natural, silver anodised aluminium, a white mark is not as clear. With a MOPA laser source, you can set very short pulse durations and so the anodised layer is not removed, simply repainted. Whilst the process of black marking is completely different from the production of reproducing colours on stainless steel, a comparable result is created.

Increased precision when melting plastics

The flexibility of the pulse duration on a MOPA laser is also very useful for producing high contrast marks on plastic materials. Typically, marking plastic with a fiber laser produces foaming and melting which comprimises the quality of the mark. With less heat being applied, less foaming and unintentional melting occurs and a more uniform mark is achieved.

In General, A laser with a MOPA source also comes with the advantage of a long life span and low levels of maintenance that you get with a regular fiber laser. If you're looking to mark a range of different surfaces and apply coloured marks to metals, then laser engraving machine with a MOPA source is definitely worth considering.

Application

Colour marking stainless steel

Annealing is a process that does not remove material during processing. The creation of colours when laser marking stainless steel with the annealing method is caused by heat application. Whilst the possibility of creating colours with a laser machine has been around for a long time, the capability to accurately precisely mark colours and to reproduce them is a newer advantage provided by a MOPA laser source.

Black marking of anodised aluminum

The top layer of anodised aluminium is usually removed by a laser to reveal a white mark. A mark of this kind is particularly visible and clear on coloured anodized surfaces, but on natural, silver anodised aluminium, a white mark is not as clear. With a MOPA laser source, you can set very short pulse durations and so the anodised layer is not removed, simply repainted. Whilst the process of black marking is completely different from the production of reproducing colours on stainless steel, a comparable result is created.

Increased precision when melting plastics

The flexibility of the pulse duration on a MOPA laser is also very useful for producing high contrast marks on plastic materials. Typically, marking plastic with a fiber laser produces foaming and melting which comprimises the quality of the mark. With less heat being applied, less foaming and unintentional melting occurs and a more uniform mark is achieved.

In General, A laser with a MOPA source also comes with the advantage of a long life span and low levels of maintenance that you get with a regular fiber laser. If you're looking to mark a range of different surfaces and apply coloured marks to metals, then laser engraving machine with a MOPA source is definitely worth considering.